-

Add.

228-31, Saneop-ro 155beon-gil, Gwonseon-gu, Suwon-si, Gyonggi-do, Korea 16648

-

Tel.

031-296-3334

-

Fax.

031-296-3335

Mold (Design/Production)

Process from Production Request to Mold Development Completion

01

A New Order

Order form

2D/3D Acceptance of Products

02

Consultation on Development

Preliminary review of problems

Parting and split line acceptance relationship

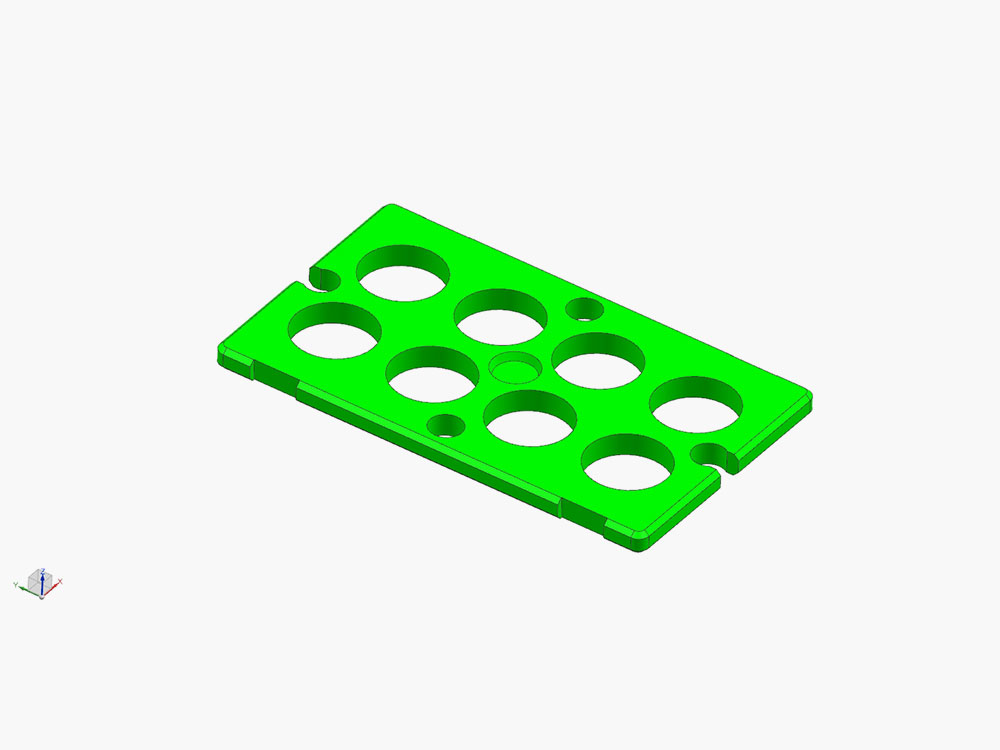

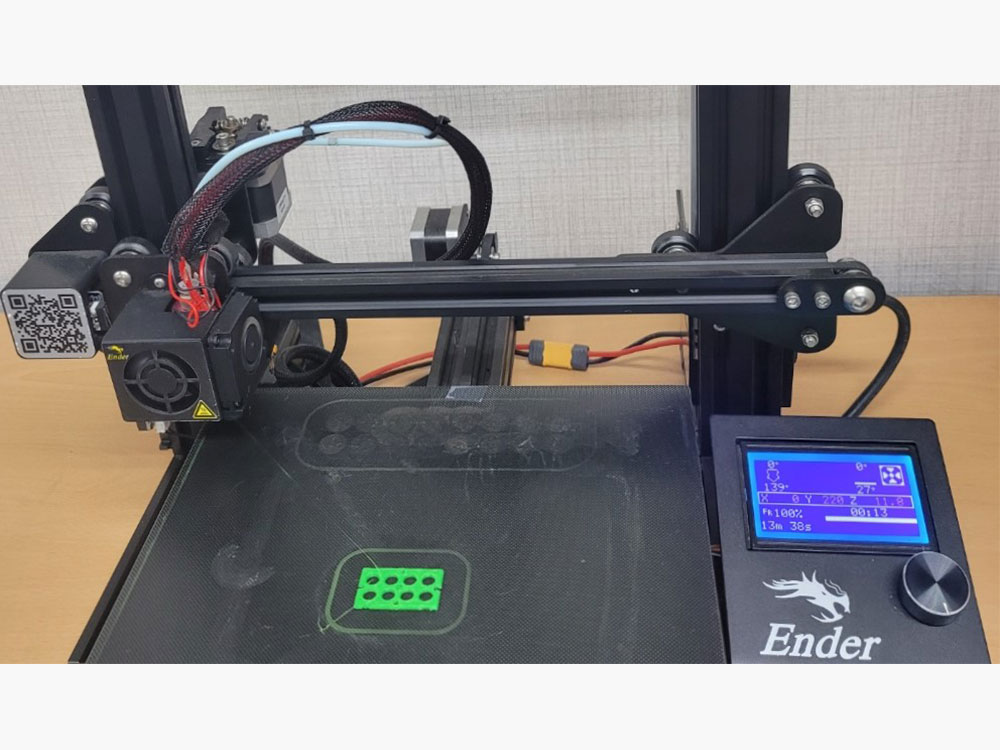

Mockup Production (3D Printer)

03

Mold Structure Conference

Injection Aspect

Mold Trouble

04

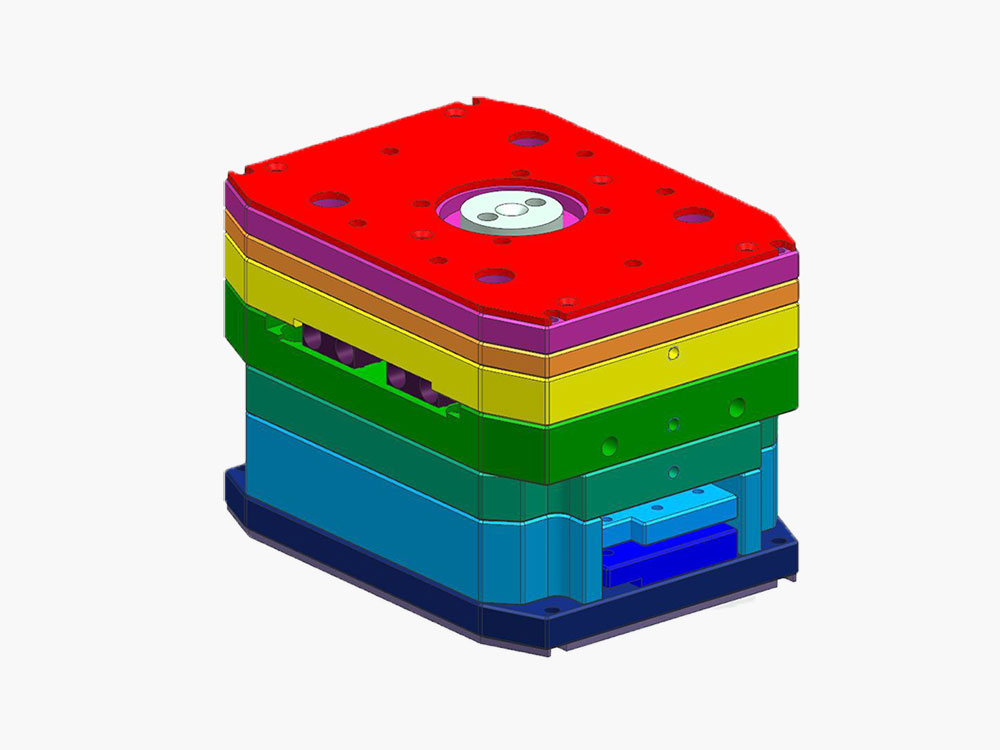

Mold Design

Full 3D Design

05

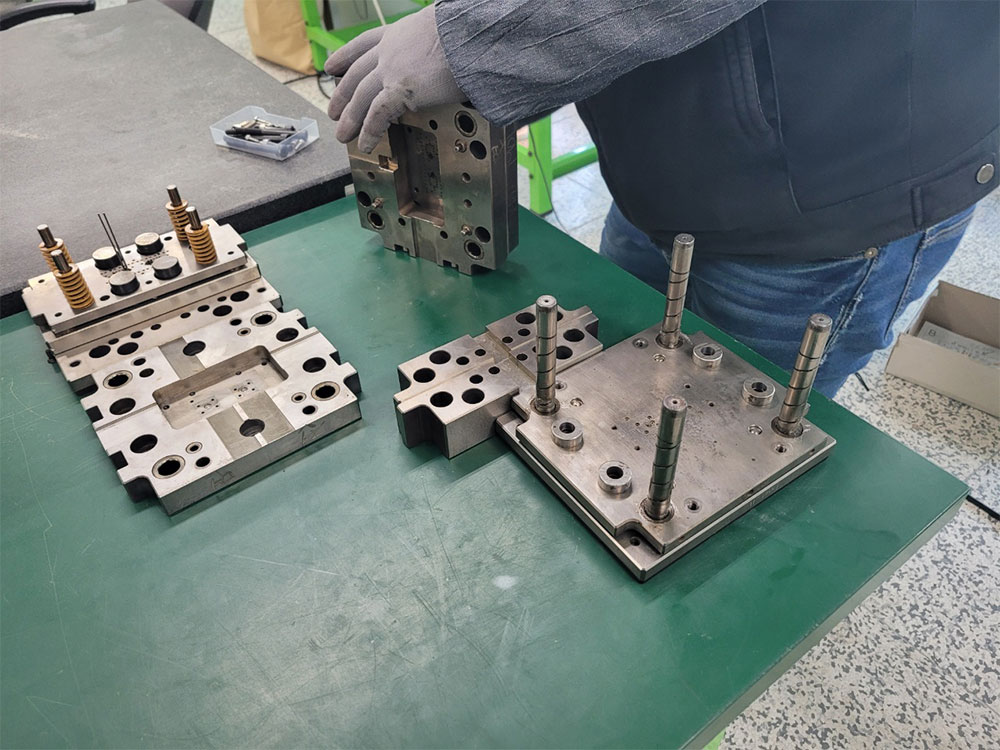

Mold Production

Core Processing

Mold Base Processing

Mold Assembly

06

Injection Molding

To Test Injection

Verification of mass production

07

Evaluation/modification

mold development completed

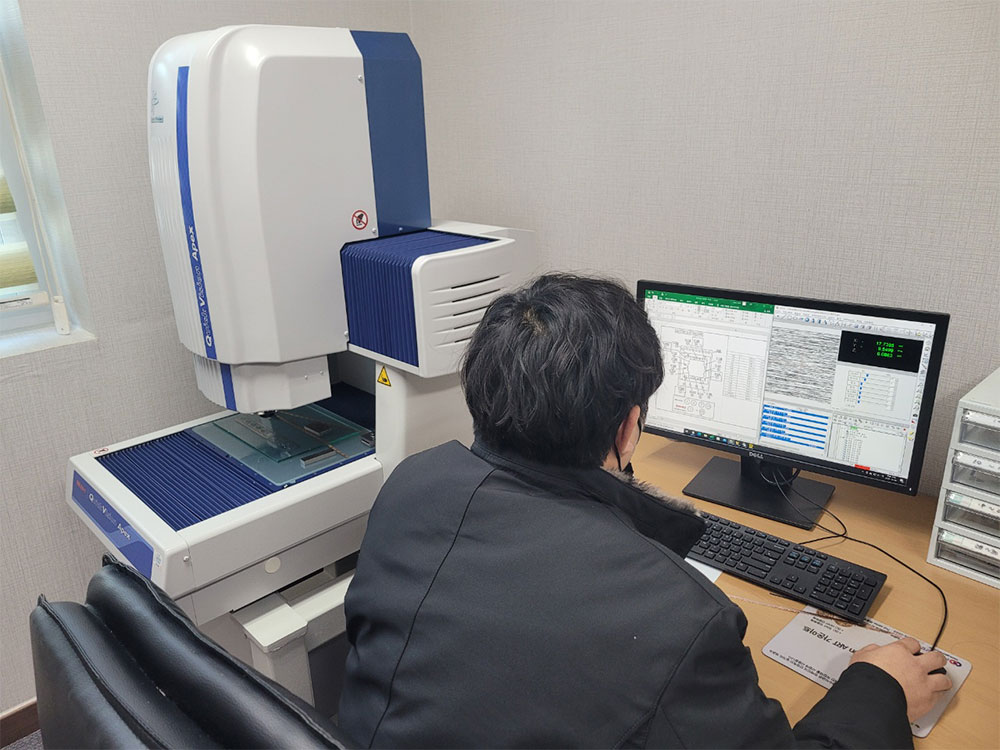

Dimension Measurement

Appearance Verification

Submission of Approval source

Mold Development Completed

Development Capability

From design to manufacture of press and mold molds, we proceed with our technology

After making Mockup products using 3D printers, you can identify product problems and minimize mold modification when making molds.

Differentiation

It is possible to develop and mass-produce ultra-small products stably using smart equipment dedicated to SANSHO KOREA (2~4Ton).

Since both injection and press can be developed, the development can be completed quickly and reliably when developing insert molds.

Performance Introduction

Mobile Connector - TYPE-C/Socker, BtoB/SIM CARD, etc

Electronic Component Connector - FPC / HDMI, etc

Bio Device - Bio Ship Container / Extraction tube, etc