-

Add.

228-31, Saneop-ro 155beon-gil, Gwonseon-gu, Suwon-si, Gyonggi-do, Korea 16648

-

Tel.

031-296-3334

-

Fax.

031-296-3335

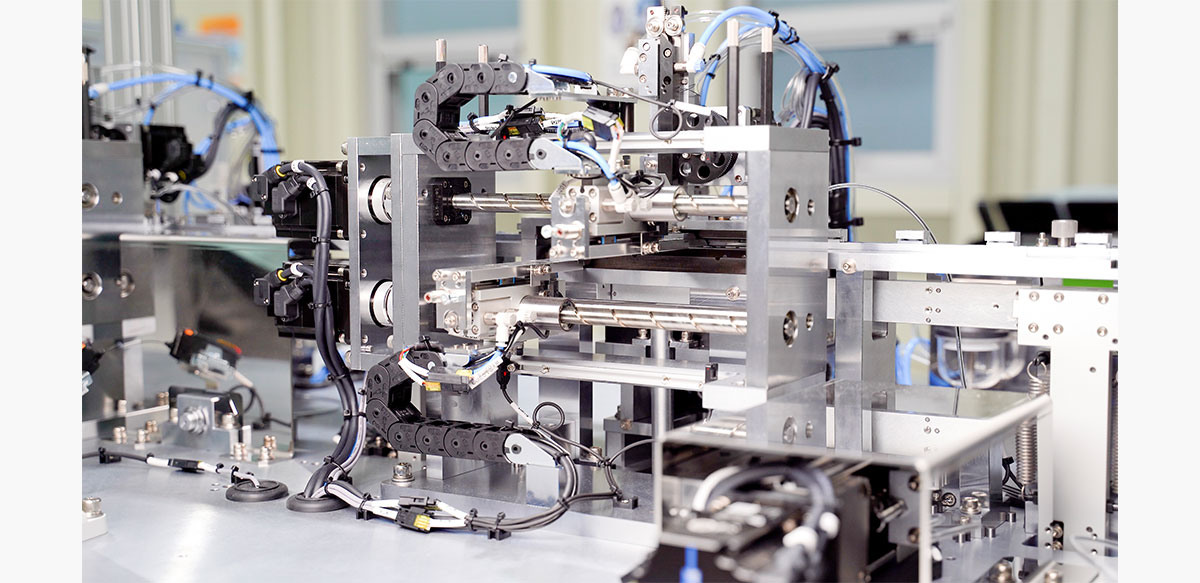

Automation Equipment (Design/Manufacture)

Based on our know-how, We provide everything to Design, Manufacture,

and improve productivity according to the needs of our customers.

Automation Equipment

You can automatically insert, inspect, and pack the pin into the housing that has been inserted using the ball feeder.

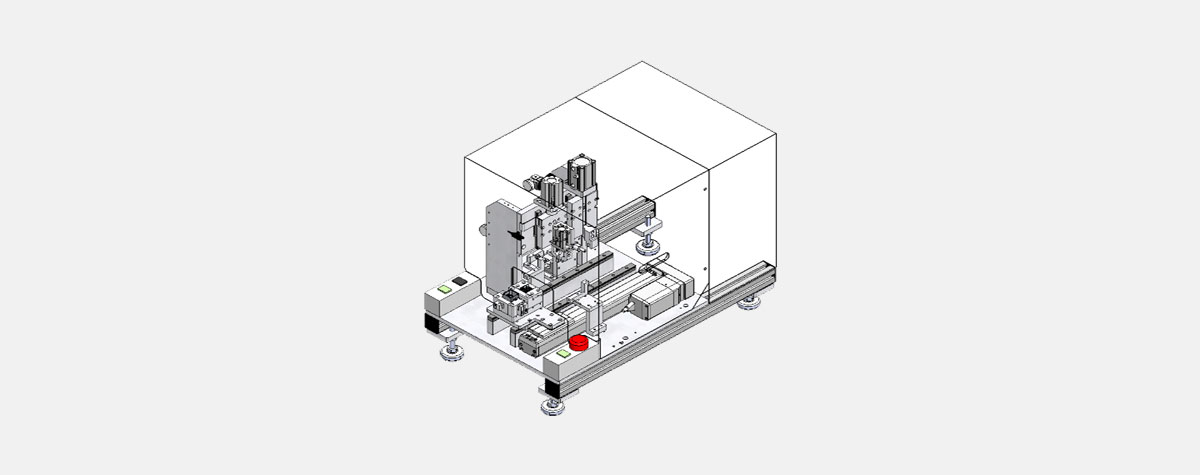

Semi-Automated Equipment

When the operator places the housing on the jig and push the SW, press the holder and dot marking.

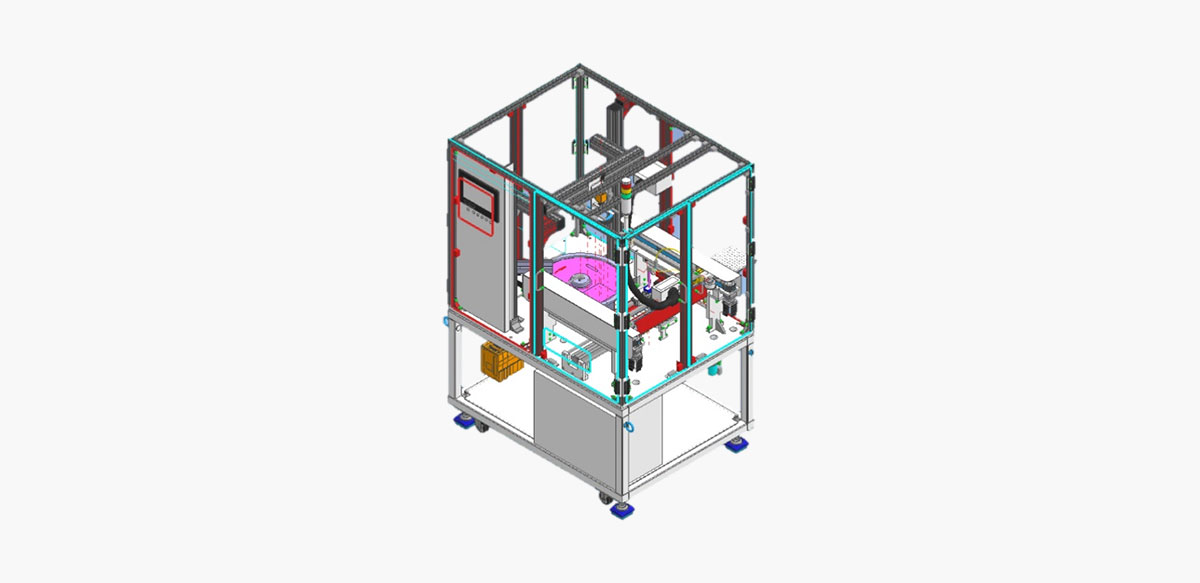

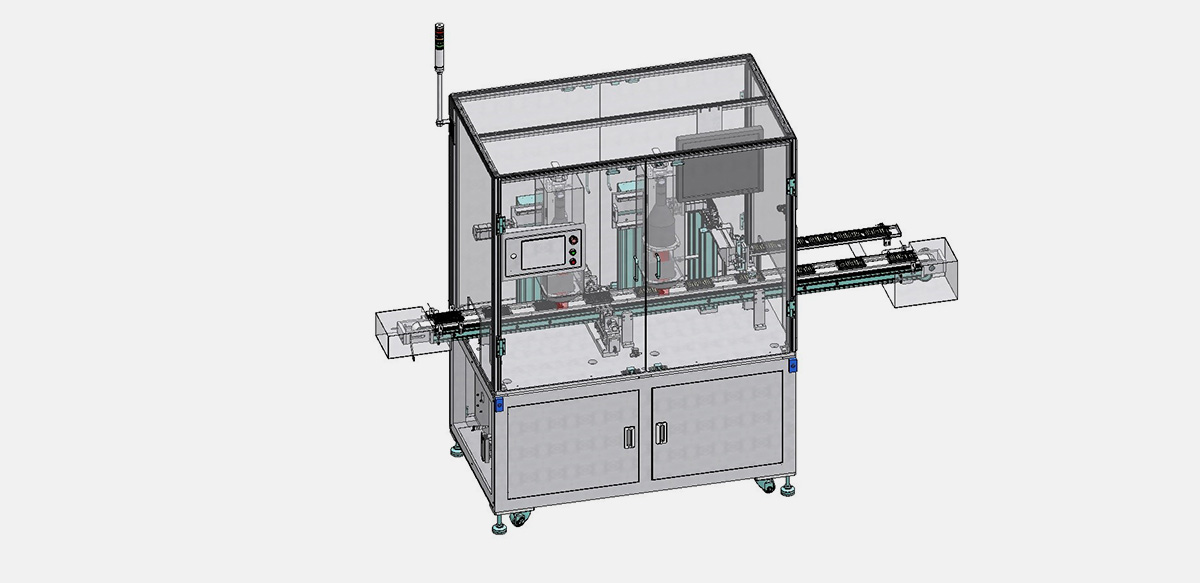

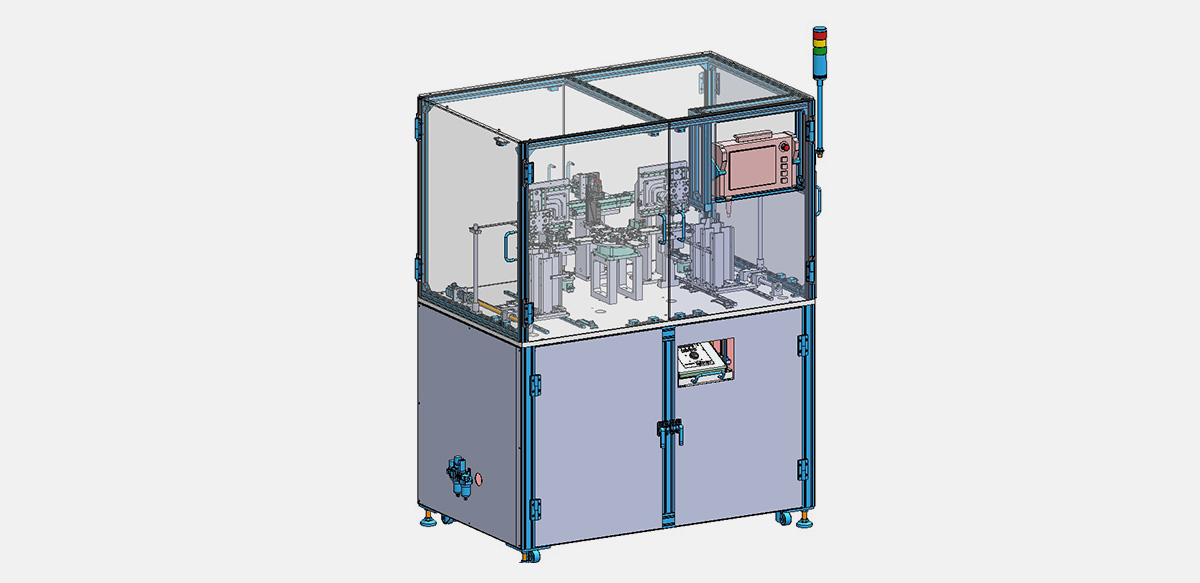

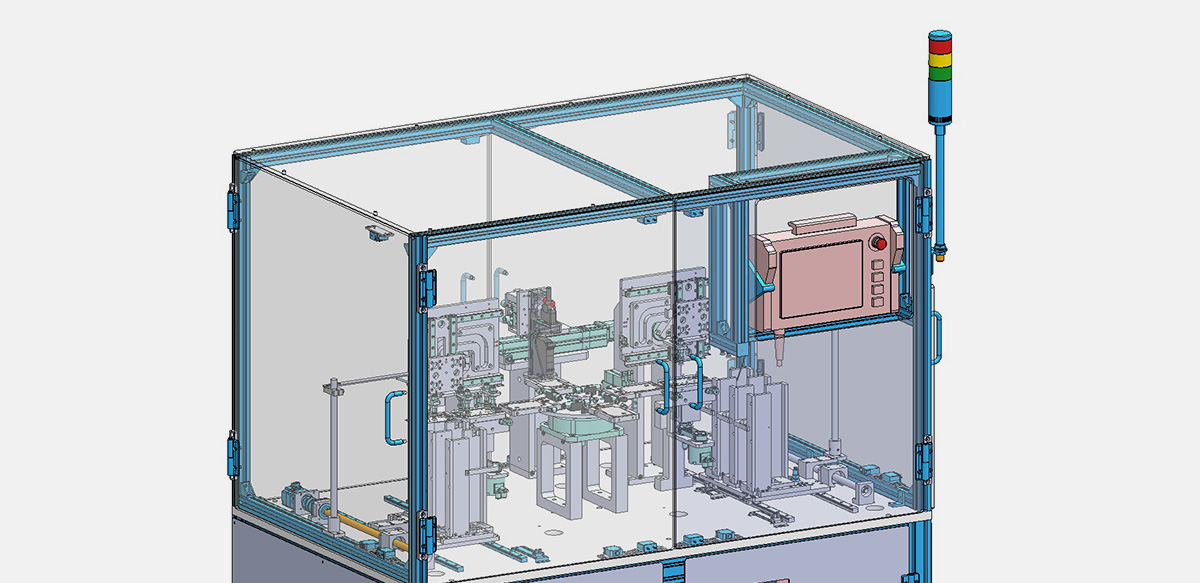

Index 6-sided Inspection & Packaging (Standardized) Equipment

The product is energized, withstand voltage is inspected, and the pitch and length are inspected on 6 sides to pack both products.

Side Inspection Machine

Inspect the product for voltage, inspect the side.

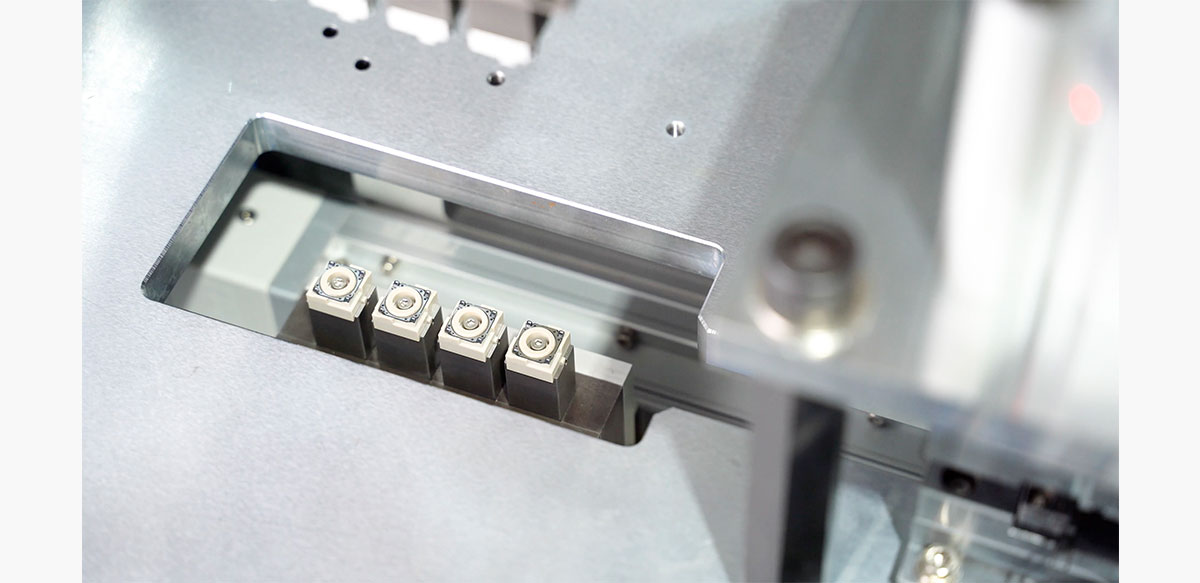

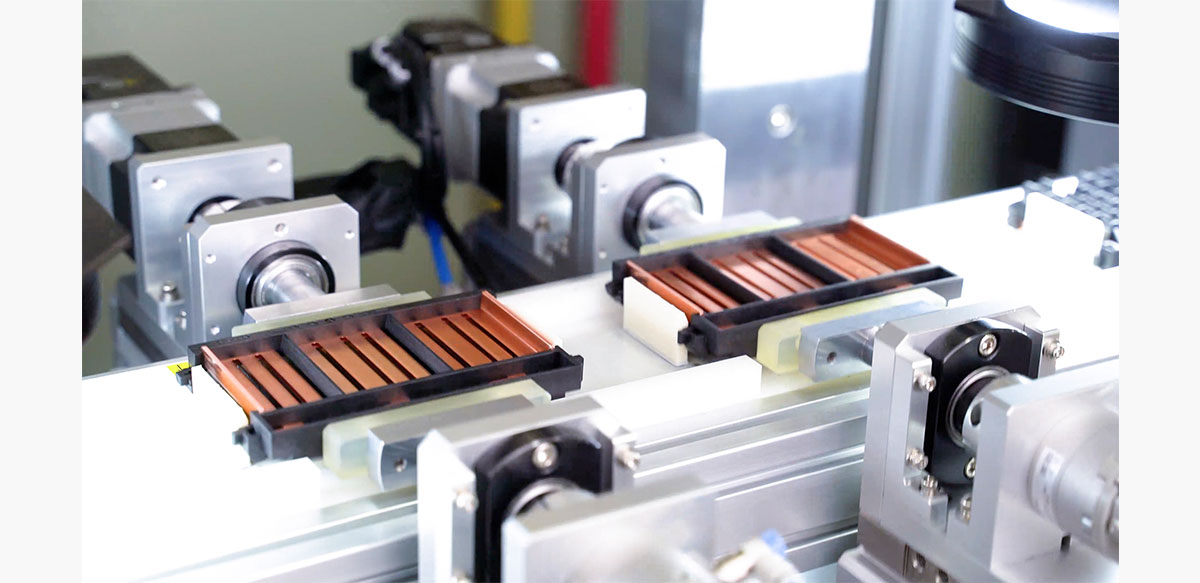

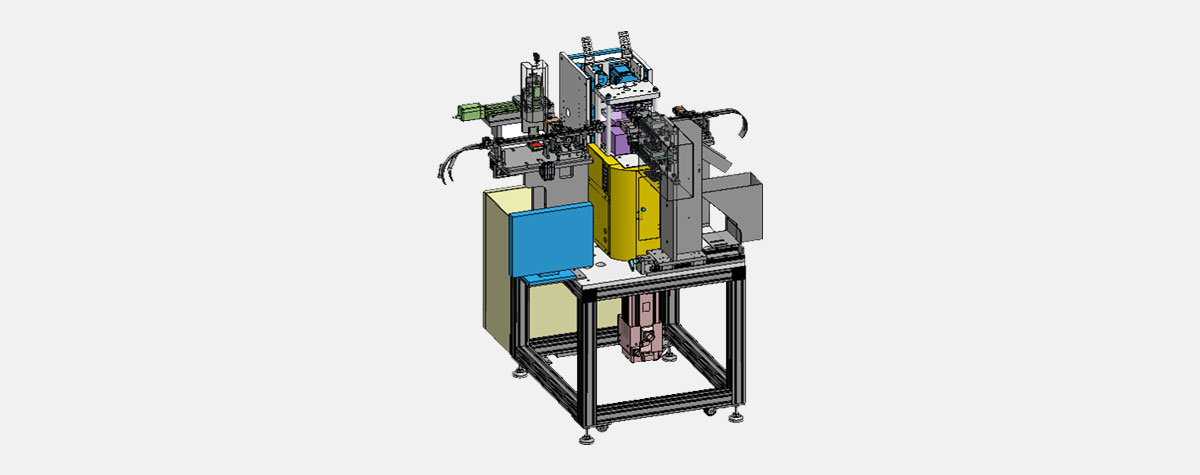

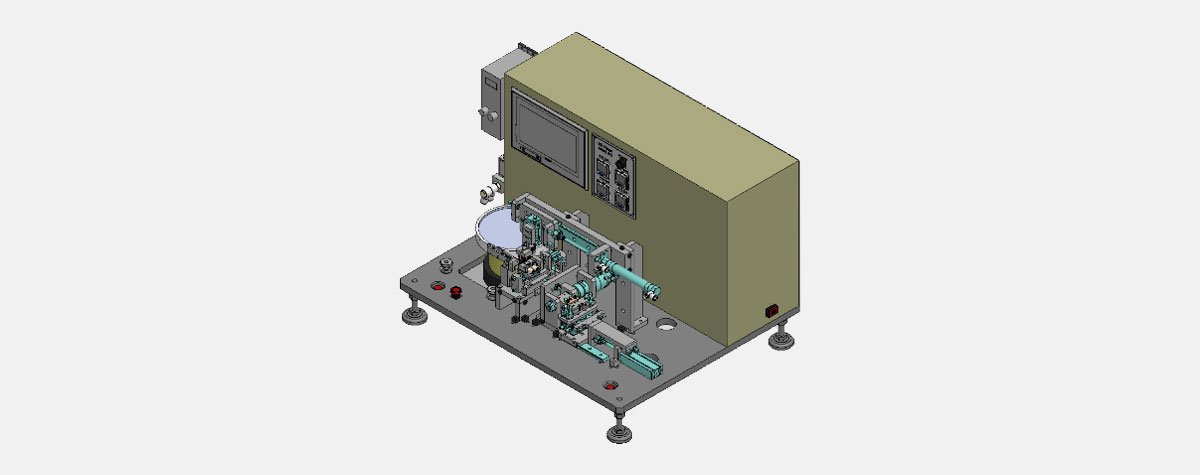

Power pin Assembly Machine

Insert pin to housing.

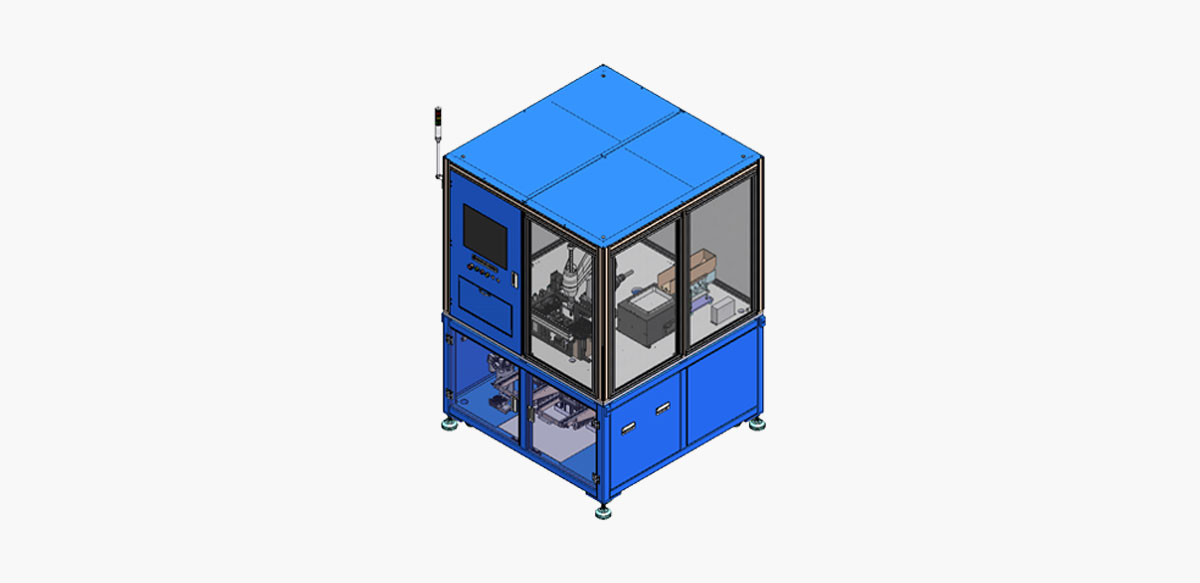

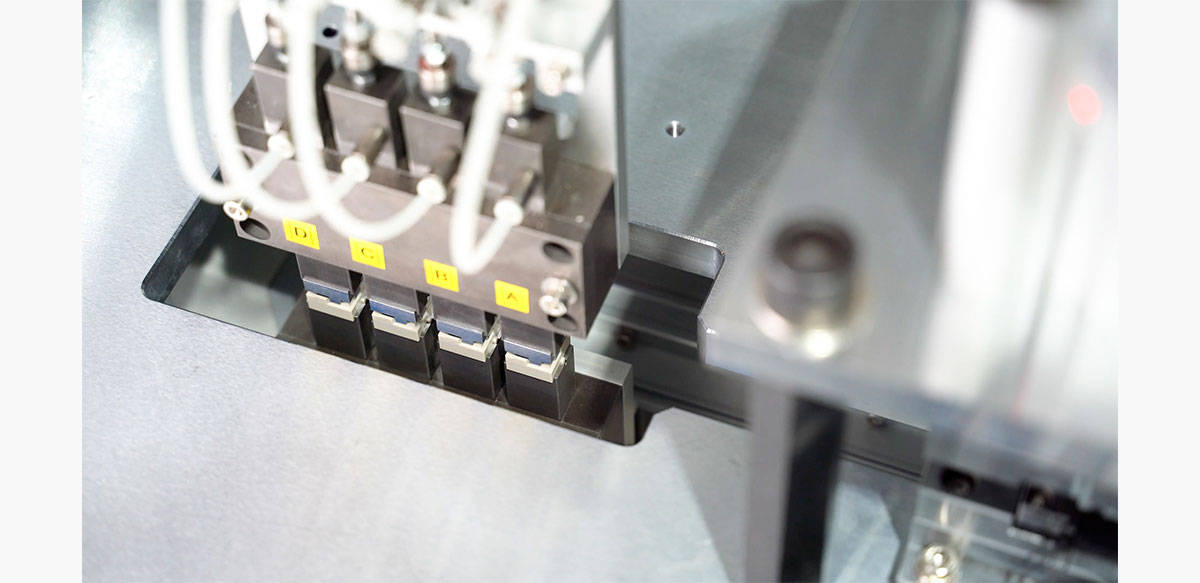

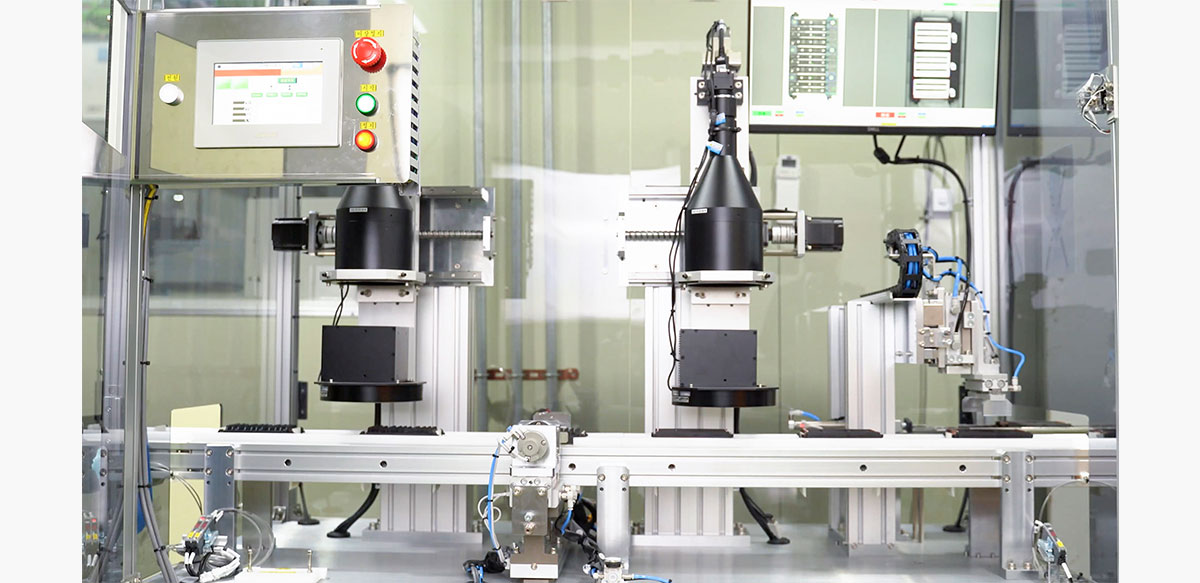

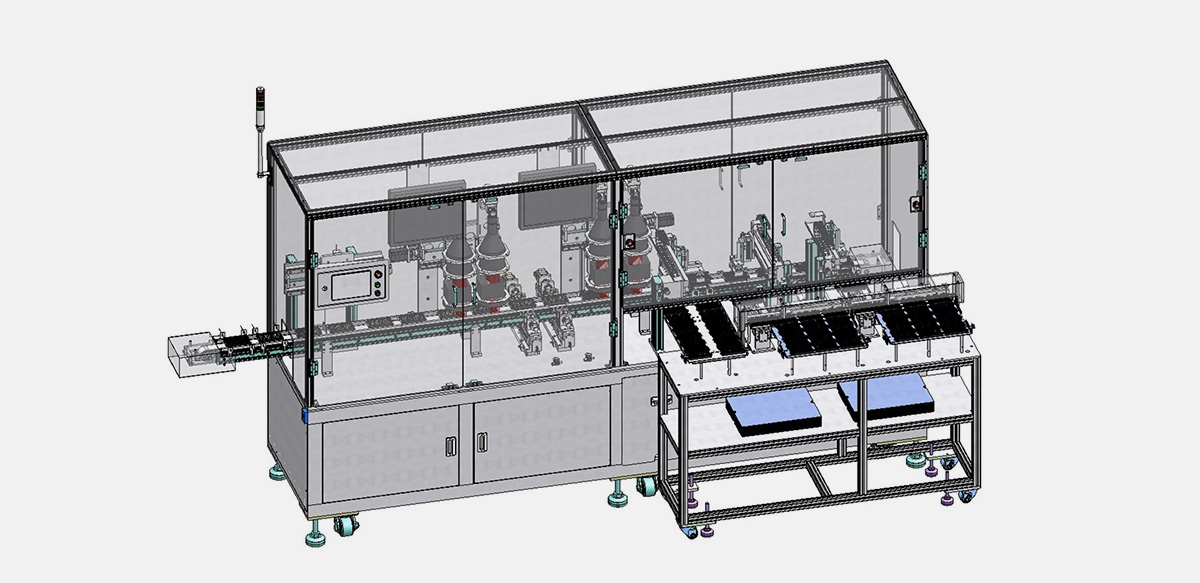

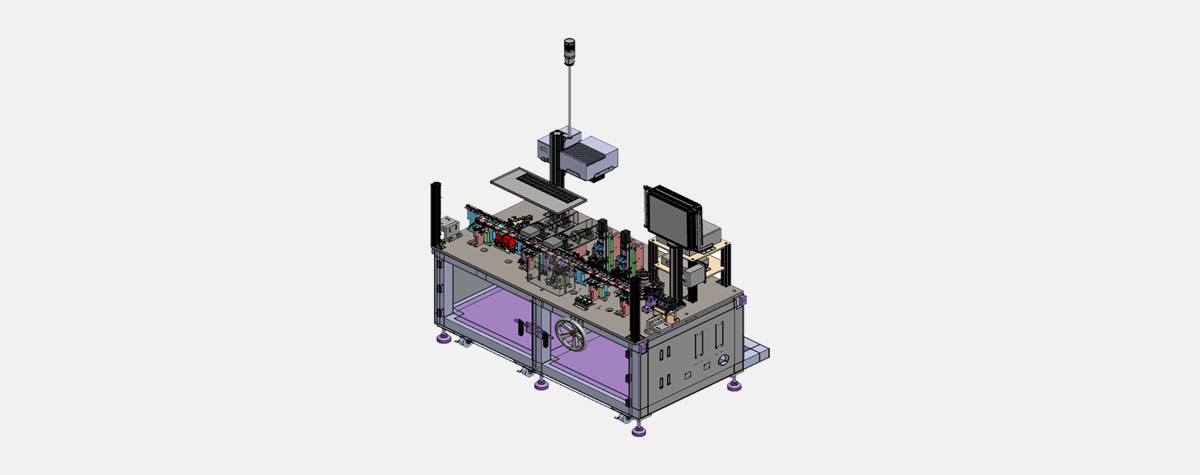

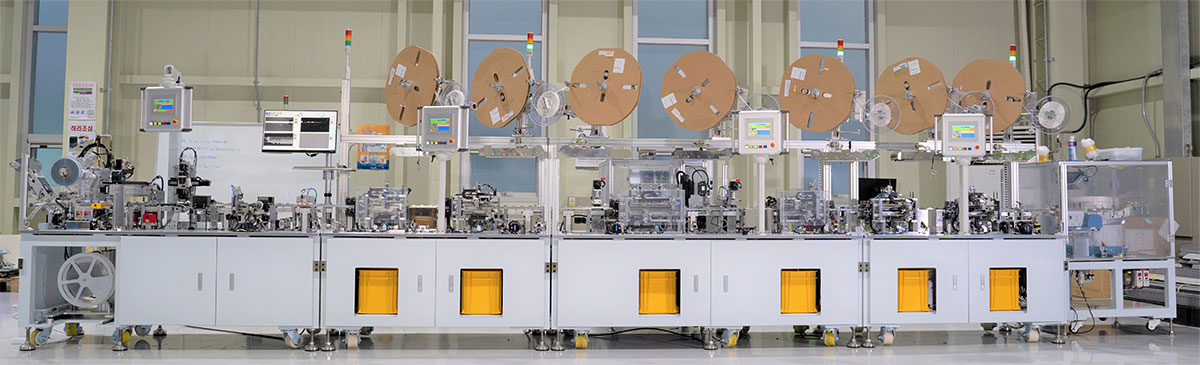

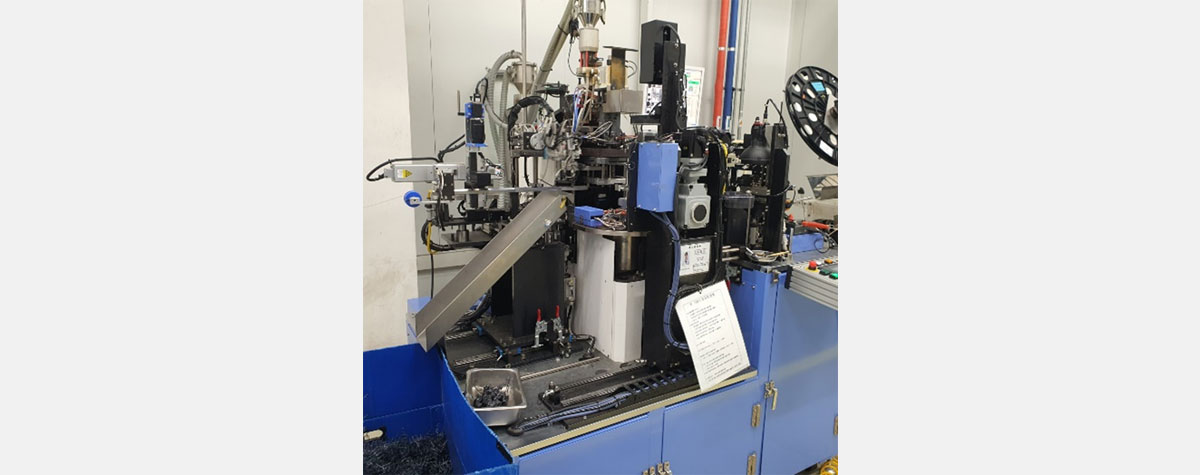

FULL AUTO LINE(Assembly & Inspection & Packaging) Equipment

Insert housing using ball feeder, insert Hold down/Power pin into housing, inspect and pack the good products.

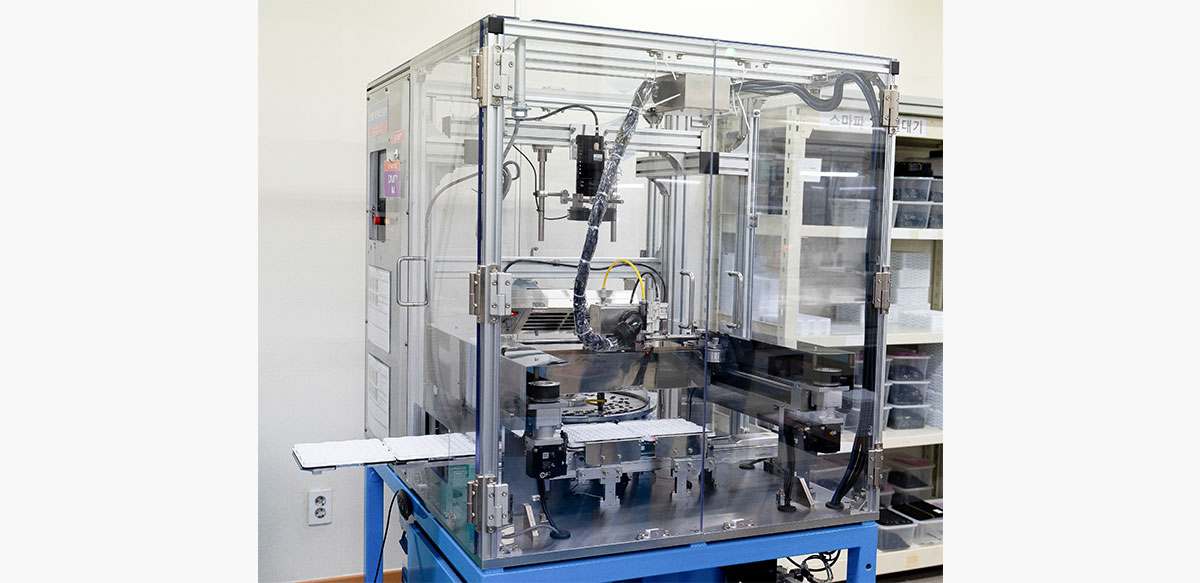

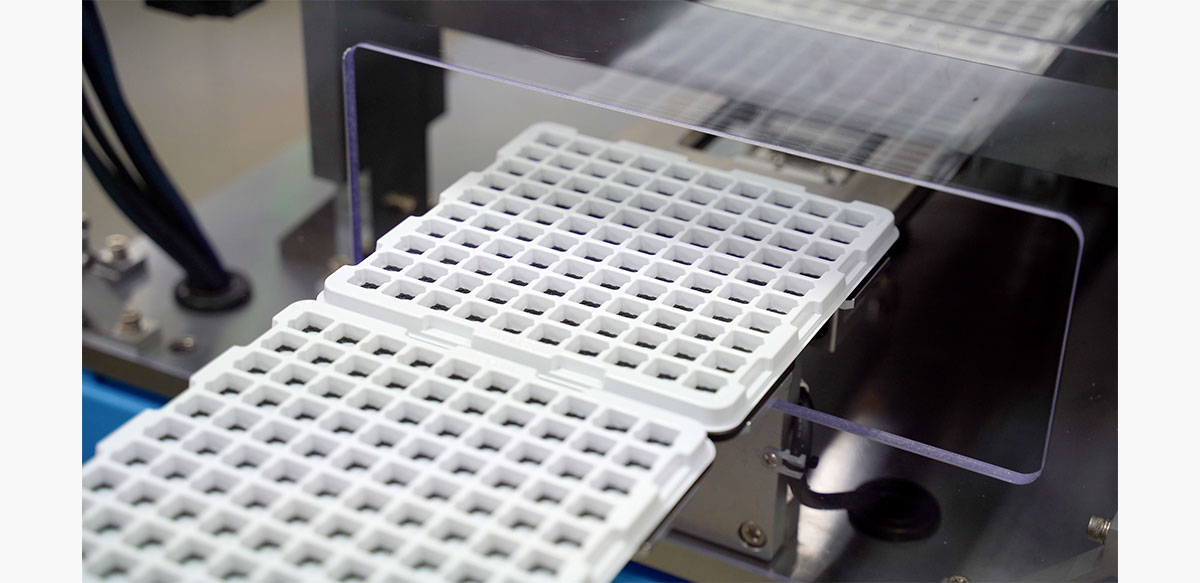

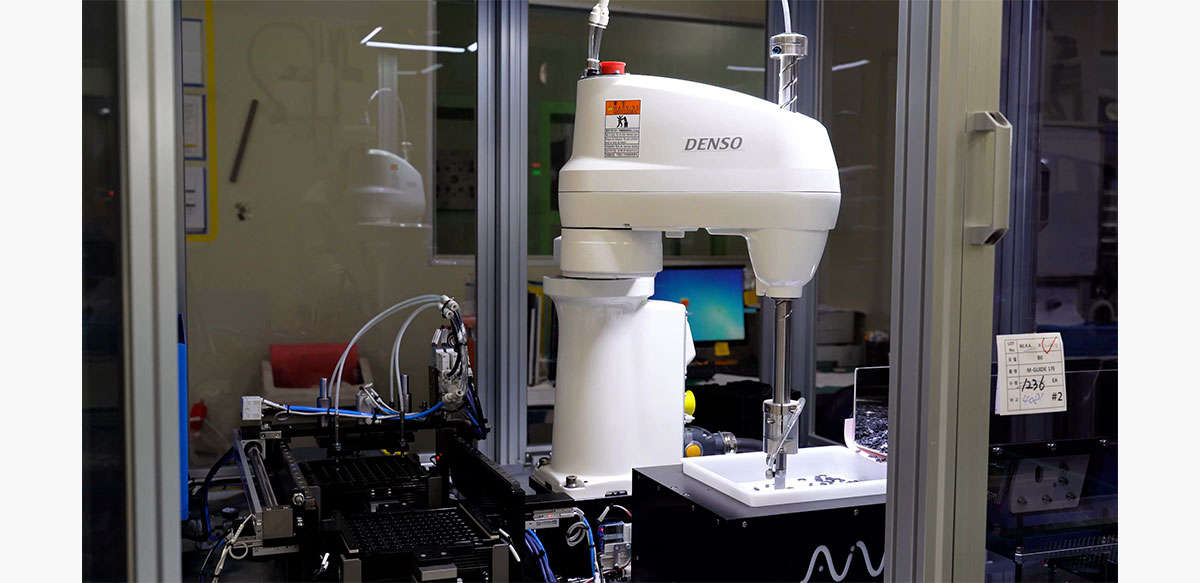

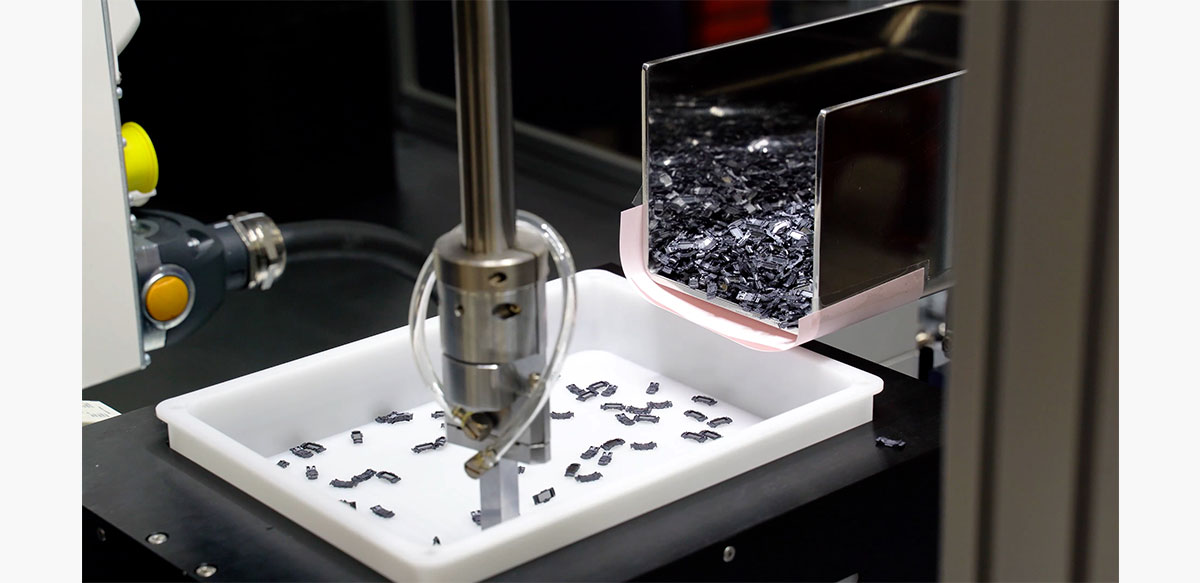

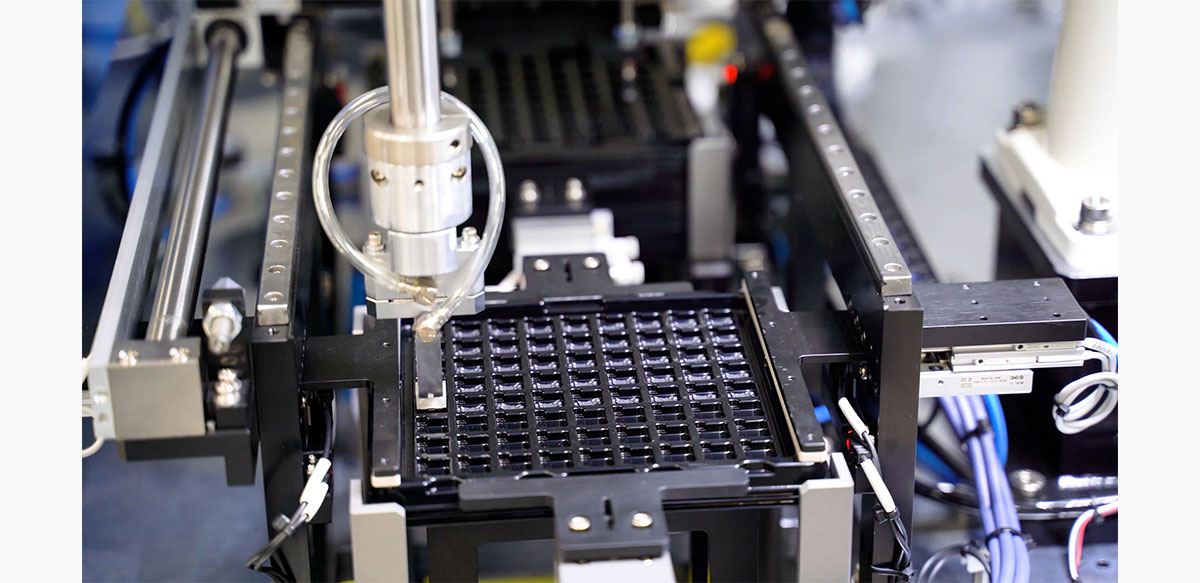

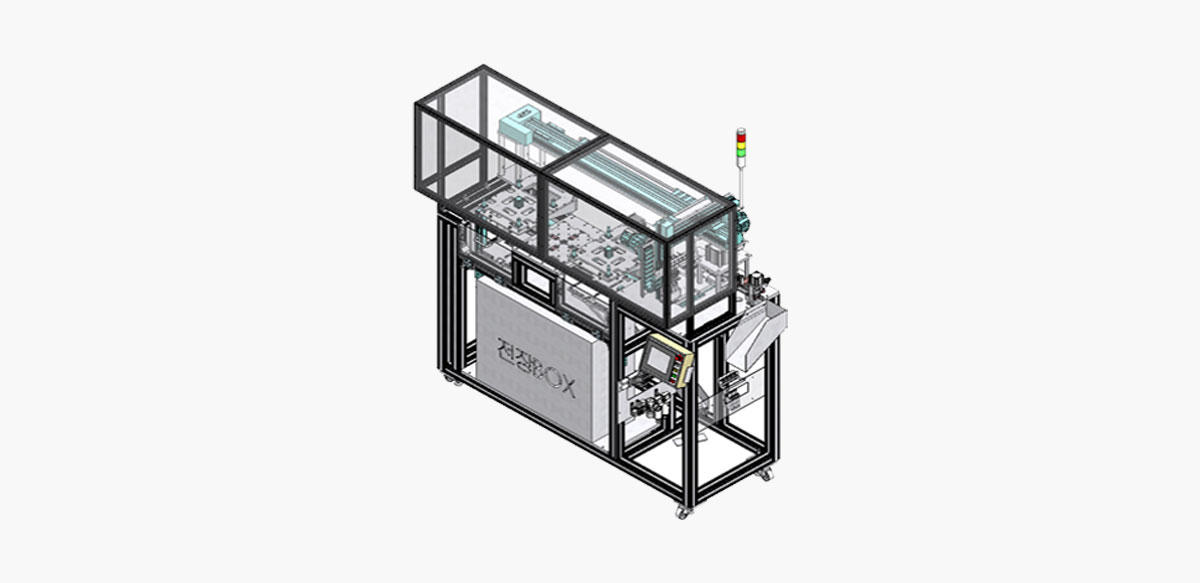

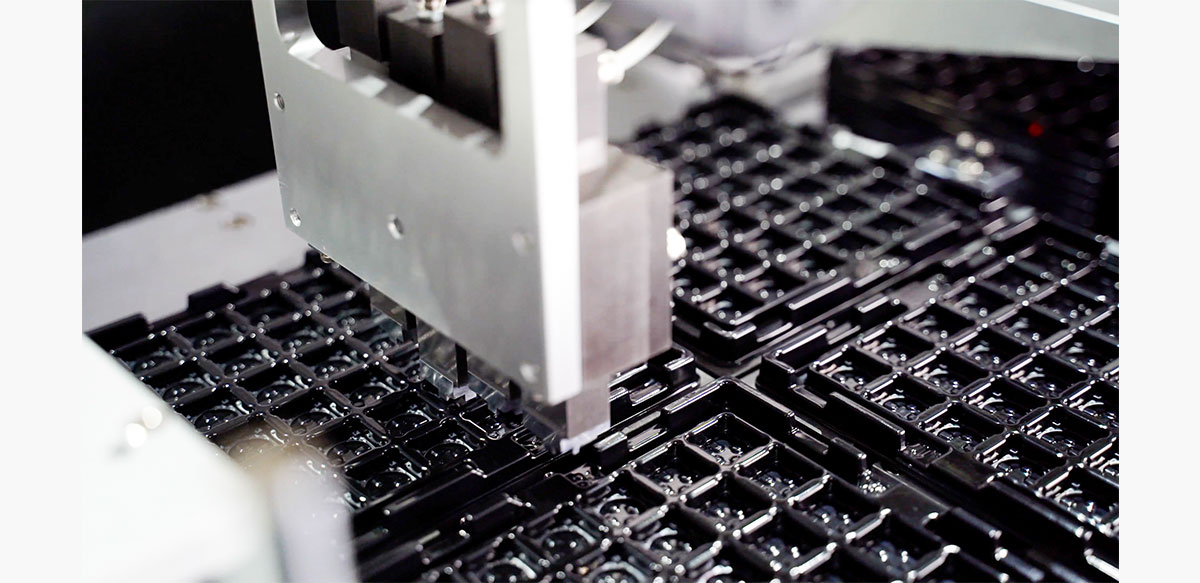

Orthogonal Robot [A TYPE]

Use a vision tester and an orthogonal robot to pack the bulked product into tray.

Articulated Robot [B TYPE]

Use a vision tester and a multi-joint robot to pack the bulked product into tray.

Cut+Orthogonal Robot [C TYPE]

Insert the injected product into the terminal and cut the product, and then use the orthogonal robot to pack the tray.

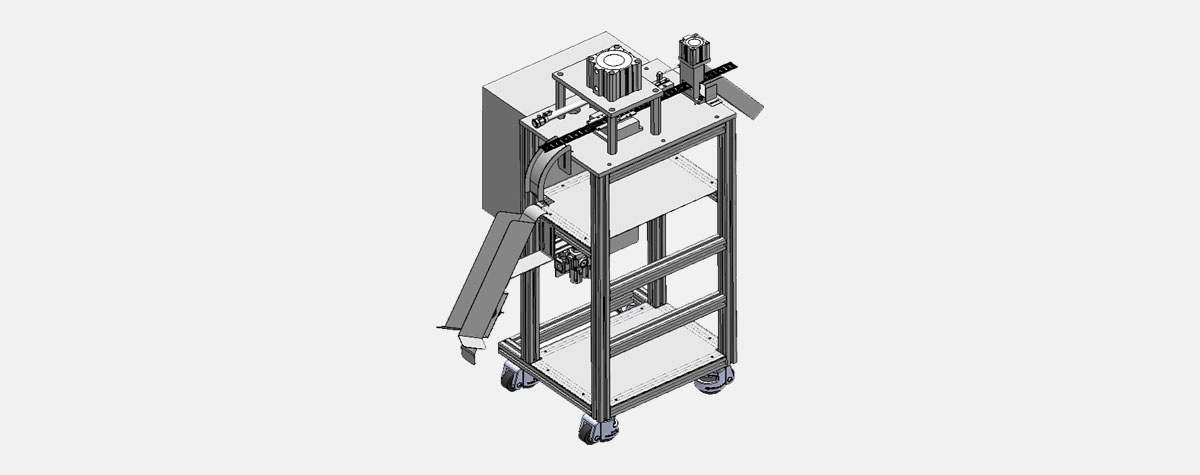

Small Smart Auto Transfer Unit

Inspect and transfer the terminal to auto for mold injection.

Index Smart Auto Transfer Device

Inspect the terminal for mold injection and transfer it to auto, and inspect the injection completed product.

Injection Product Cutting Machine

Use cutting for each cavity to cutting after injection.

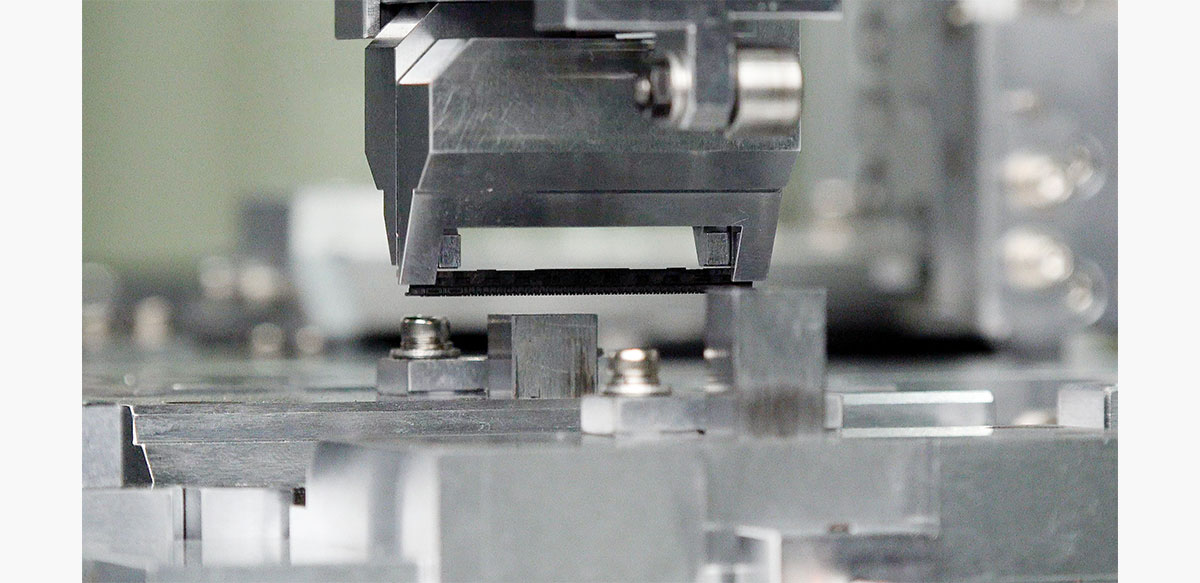

Terminal Reveting Machine

Use auto to reveting the terminals in column 1 or 2.

Terminal Pierching Machine

Pierching the terminal to auto for revet.

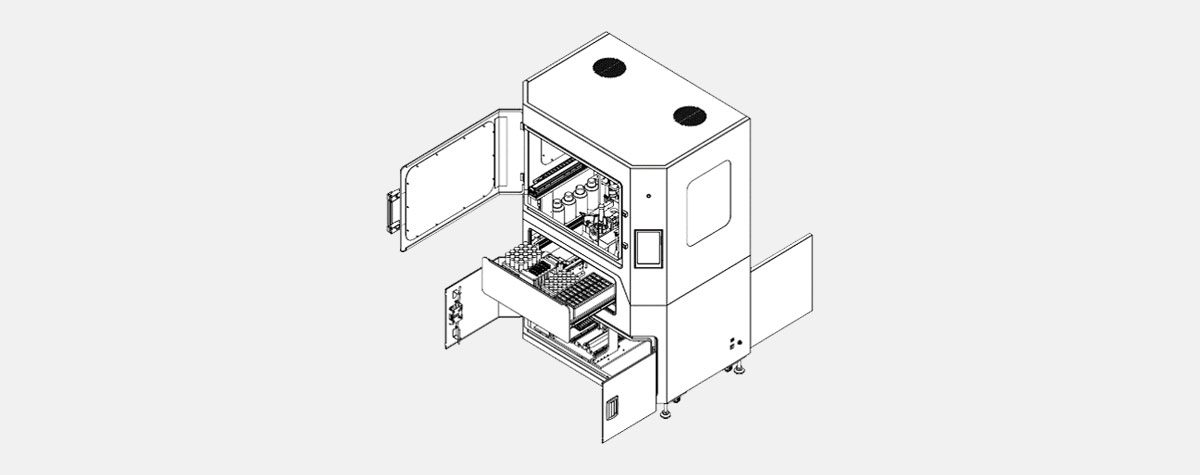

Sputum Specimen Full Auto Machine (F500)

Sample sputum collected from suspected tuberculosis patients is pre-treated automatically and standardized (Nalc-NaOH method), and samples are automatically injected into the solid medium Ogawa for culture that automatically paints and fixes samples on glass slides.

Para tube filter Insert Semi Auto Machine

The FILTER is injected using a ballpeter, and the operator puts the PARATUBE into the jig and presses the button to INSERT the FILTER into the PARATUBE.

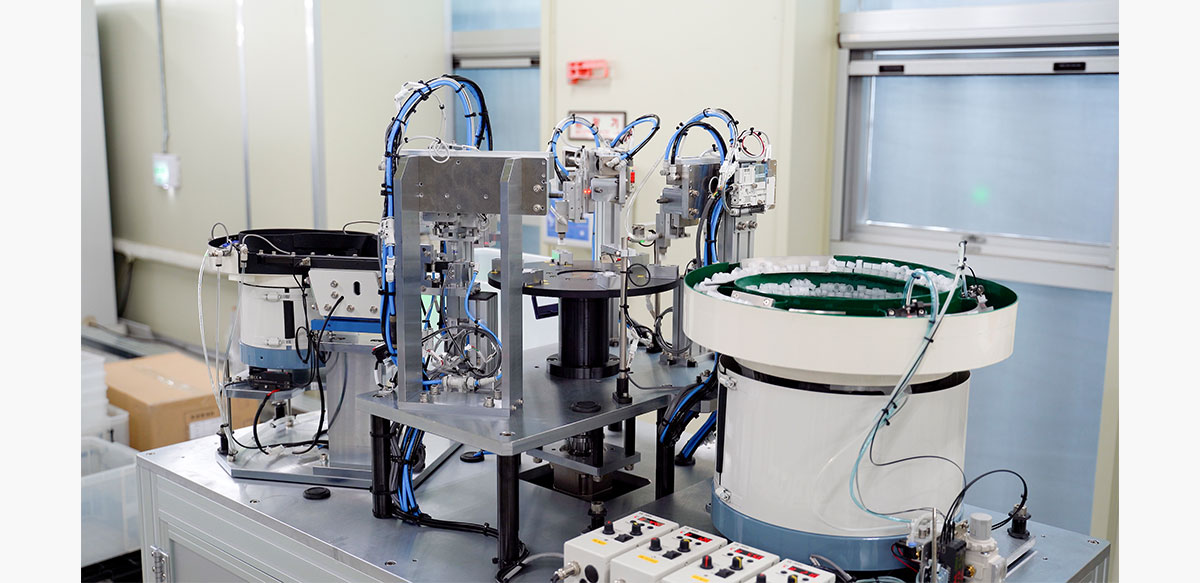

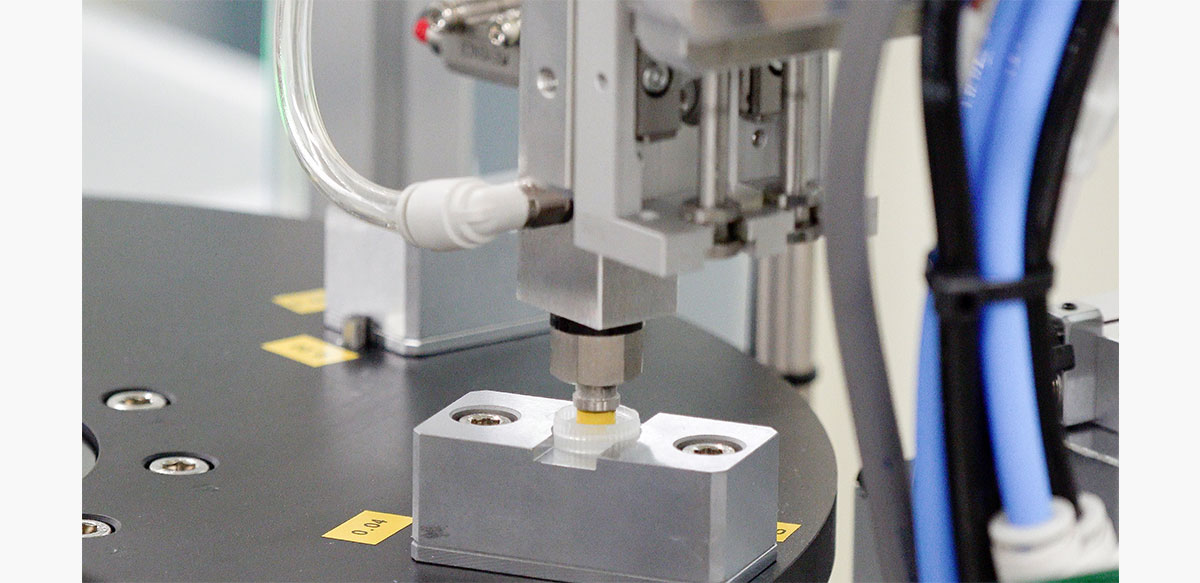

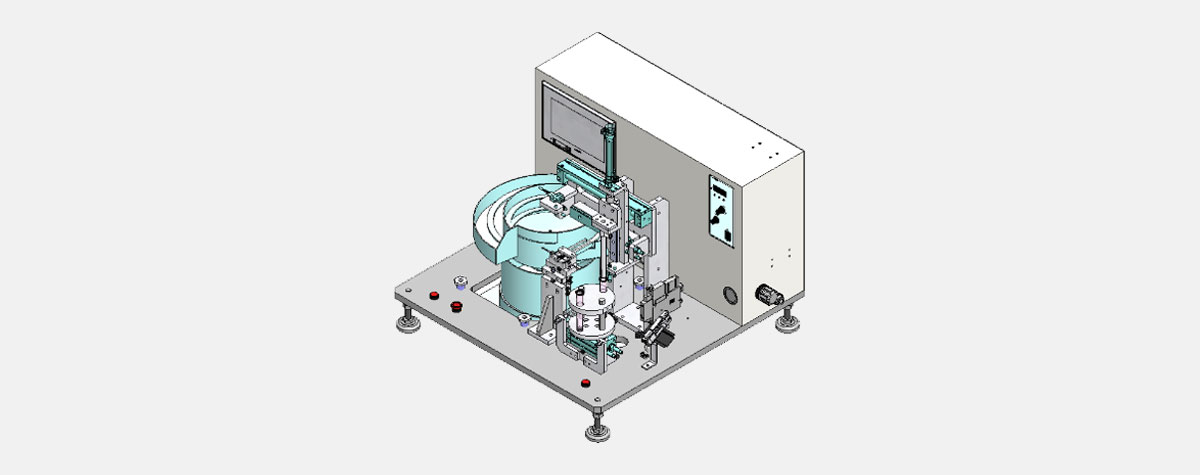

Vial O-Ring Insert Machine

Use the O-Ring ball feeder and the Vial ball feeder to settle the O-Ring on the Jig and insert the O-Ring with auto on the O-Ring.

Automotive Battery Busbar Vision Inspection Machine (1Line-1WAY)

After the operator settles the product on the conveyor belt, the product is determined to be good and defective using a vision checker.

Automotive Battery Busbar Vision Inspection Machine (1Line-2WAY)

After the operator lands the product 2EA on the conveyor belt, the product is determined and defective by using a vision checker, and the product is packaged.

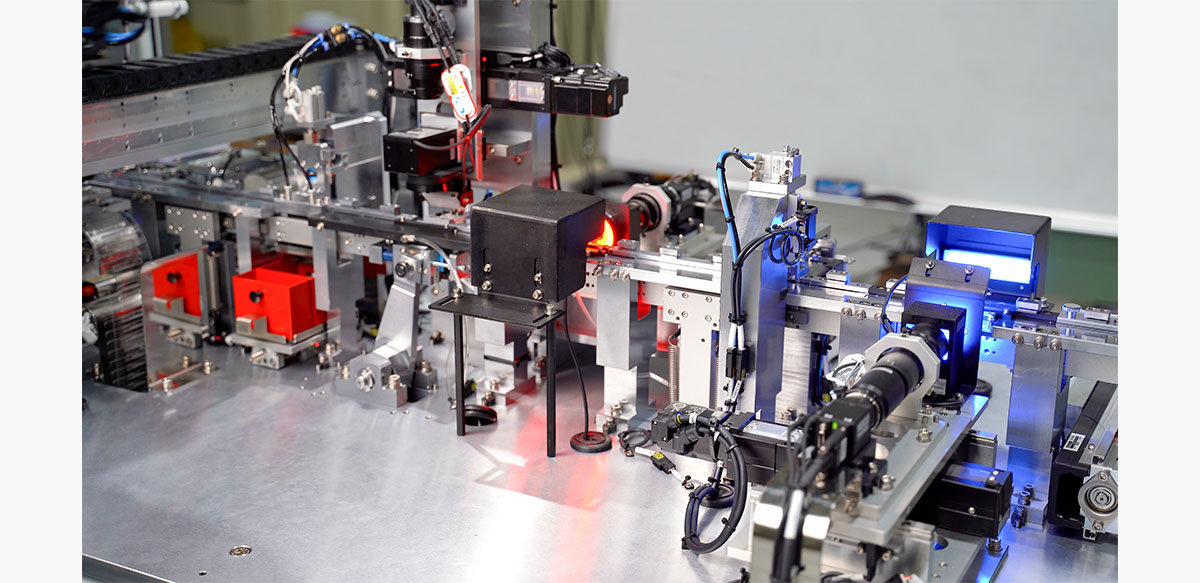

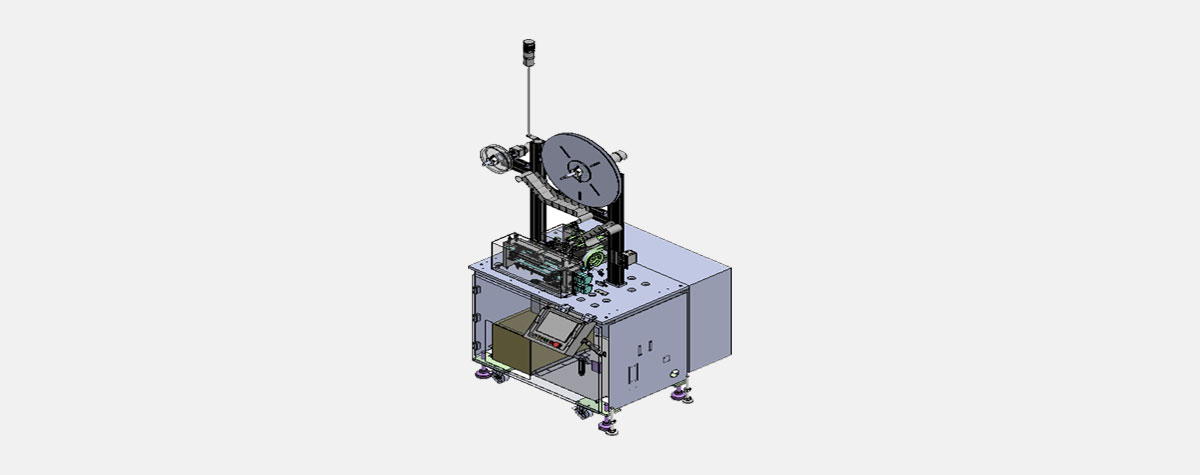

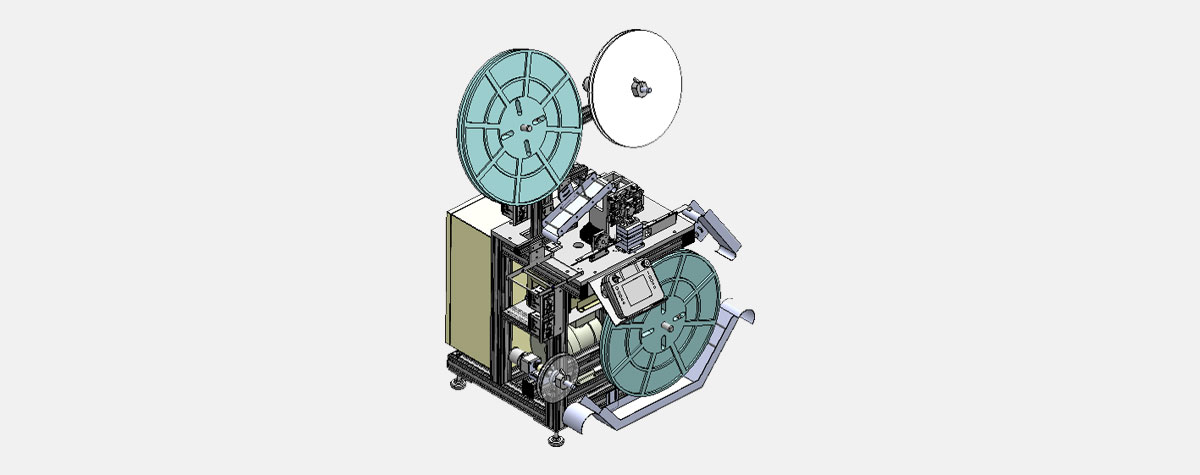

FILM QR MARKING M/C

Automatically feed the FILM to QR mark the FILM in its designated position and eject the FILM.

HINGE INSERT M/C

After the TUBE is seated on the jig and the button is pressed, the HINGE supplied using the ball feeder is INSERT.

Process from production request to completion of Automated Equipment

01

Consultation

Consultation with the client on specifications

2D/3D reception of product

02

Equipment Design

Technology Laboratory

Equipment Design

03

Equipment Design Review

Concept DR for accuracy of design,

assembly and electrical Equipment

Concept DR with Customer

04

Parts Manufacturing & Assembly of Equipment

Order processed and purchased products

Assembling by adjusting

and measuring equipment for accuracy

05

Attendance of the client company

Final inspection of equipment

06

Equipment Delivery (Installation)

Supply and installation of equipment

to the client company

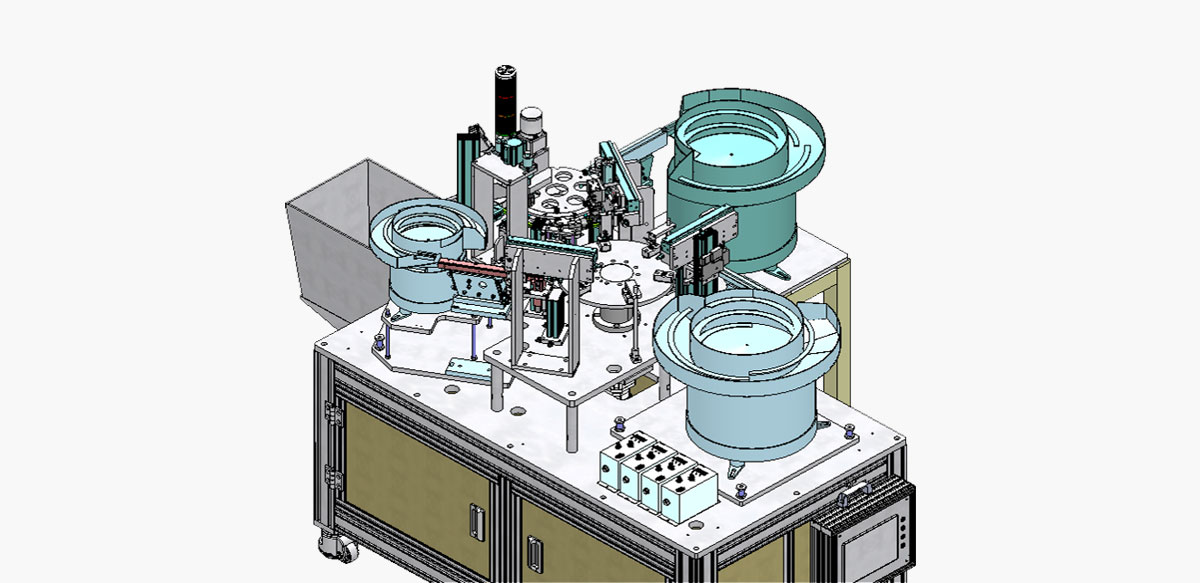

Development Capability

Automation facilities that inspect and pack BtoB and automobile connectors can be designed and manufactured with our own technology.

Camera module products administered in bulk can be aligned on the tray using (orthogonal) robots and vision cameras.

Differentiation

We can back up efficiency and quality improvement such as design, assembly, and inspection with our own technology.

Performance Introduction

Automotive Connector : Assembly+inspection+packing machine, HOLDER INSERT semi-automatic, etc

BtoB Connector : 6-sided inspection + packaging machine, side inspection machine, etc

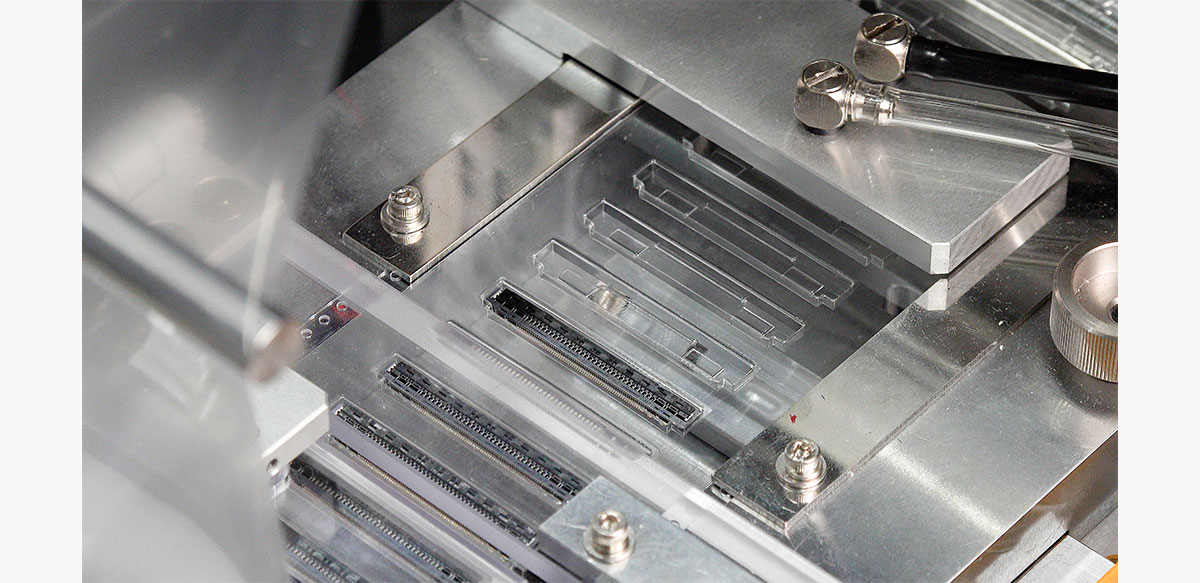

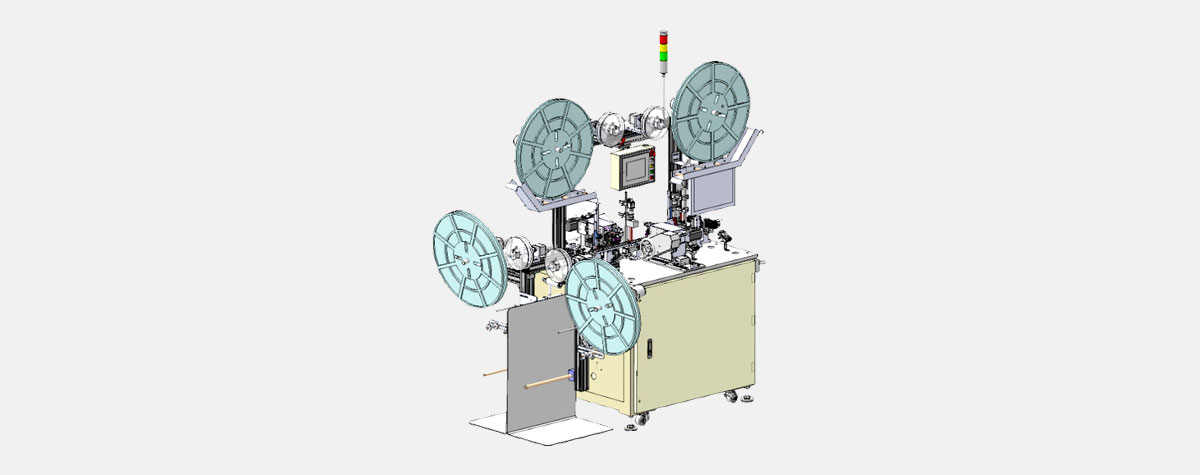

FPC Connector : Assembly + Inspection + Packaging Unit (FULL AUTO)

Camera Module Packaging : product TRAY packing machine, product CUTTING+TRAY packing machine, etc

Injection-related Equipment : AUTO transfer device for small/index injection machine, injection terminal product CUTTING M/C, etc

Bio Equipment : sputum sample FRLL automation device (F500), PARATUBE FILTER INSERT M/C, VALO-RING INSERT M/C, etc

Others: Automotive Battery BUSBAR VISION INSPECTION M/C, FILM QR MARKING M/C